Behind the Scenes of our Seed Filling Department

January is a busy time for us with our new spring catalog hitting mailboxes and gardeners around the country planning and ordering for their upcoming garden. Seed is continuing to roll in, and our manufacturing department (what we internally refer to as ‘seed filling’) is running double shifts to keep seed packets stocked on our shelves.

Our main goal is to get seed out the door and into gardener’s hands as quickly as possible. So, let’s take a look behind the scenes of how our seed filling department helps make that happen.

How are our seed packets created?

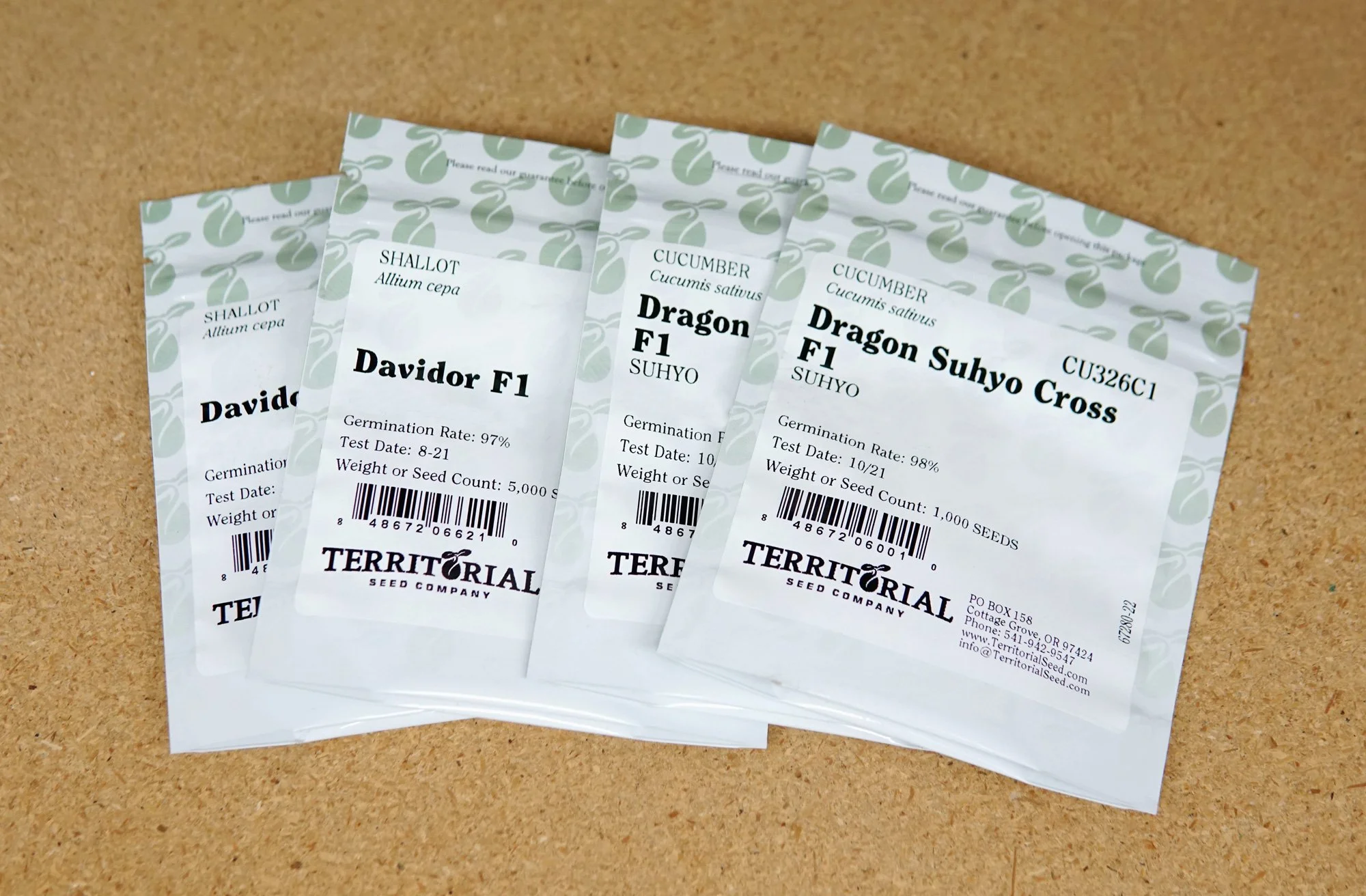

We print variety information on all our seed envelopes in house. We have three different ways of printing packets.

Jet Press – Our Jet Press (an oldie but a goodie!) is used for large runs (usually 1500 or more packets) and can print over 15,000 packets a day. The machine inks rubber plates containing the text and price information, which is then transferred onto the envelopes. The Jet Press prints our most popular size of envelope, so it is our go-to for kicking off the new season.

Digital – We love our Jet Press, but given its age, it can sometimes break down. Anytime that happens we switch to digital. Our digital inkjet printer can print multiple sizes of seed envelopes and can print custom packets upon customer request.

Zebra – This label printer is used for our largest commercial orders, cover crop bags, seed tapes, and any other ‘bulk’ sized packaging such as our larger sizes (1/2 pound, 1 pound, etc.) of flower mixes.

Is there anything that must be done before a variety can be put into a seed packet?

Yes! All crops are germination tested and certain crops are tested for disease.

Disease testing – Due to a brassica quarantine that is in effect in the states of Oregon and Washington, all our brassica seed is tested for a fungal disease called black leg. The seed must be deemed black leg-free before we will sell it. There are certain other crops (tomatoes, lettuce, peppers) that our farm will opt to test for the most common diseases found in our area. These tests aren’t required, but we choose to go above and beyond to offer only the healthiest seed.

Germination testing – To ensure we sell only top performing seed, we have established germination standards that are higher than prescribed by the Federal Seed Act. We test every lot of seed we sell.

How do we fill seed packets?

We fill packages one of two ways: either by machine or by hand.

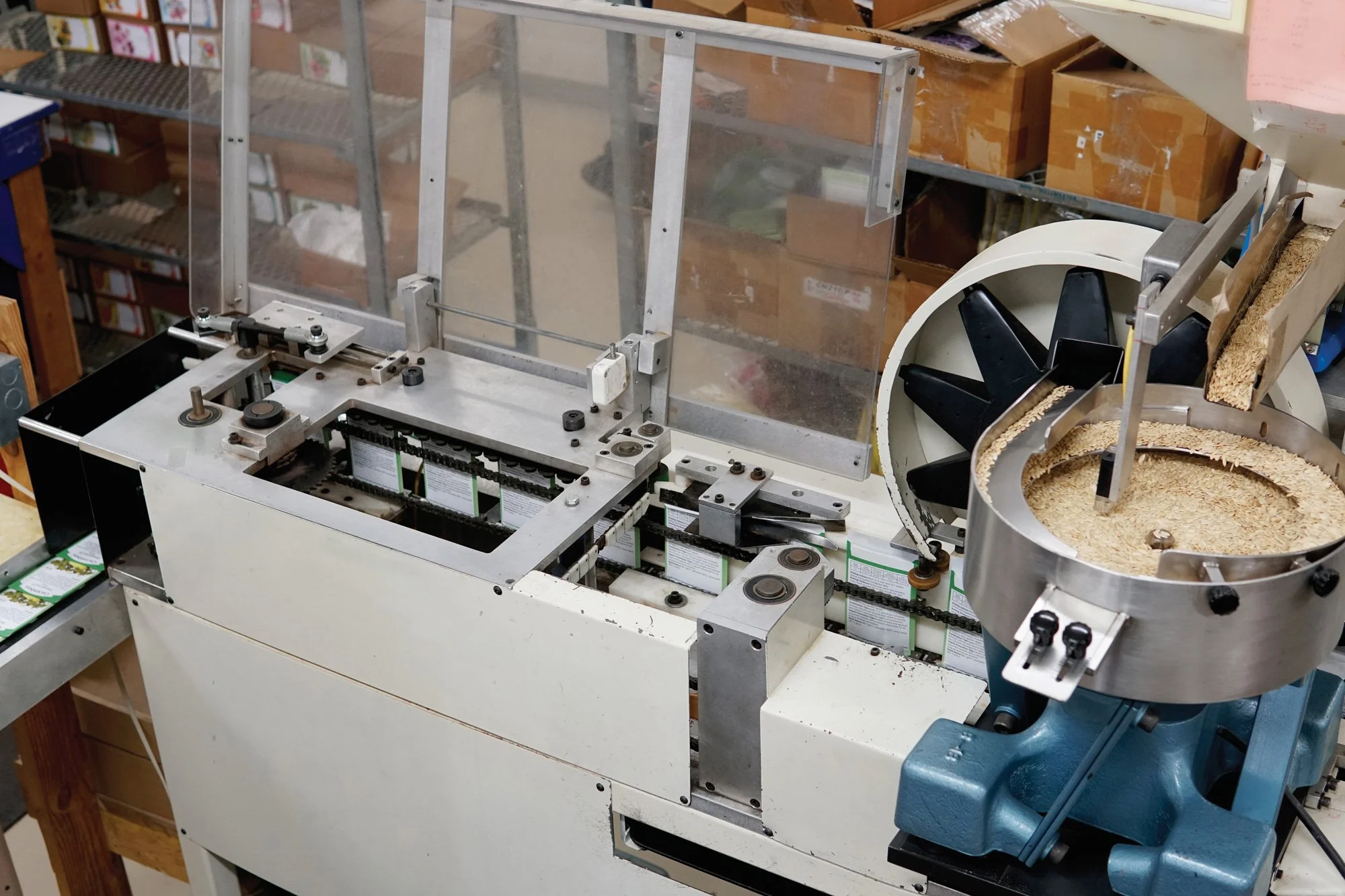

We have Seed Pack machines that fill packets by weight (1/2 gram, 1 ounce, etc.). We have machines that handle smaller seeds like lettuce, tomato, etc. and others that are made for larger seed like peas and corn but can also handle most sizes of seed except for the smaller seed (lettuce, tomatoes, carrots, etc.). For these machines, the bulk seed starts in a hopper, falls into a vibrating bowl and down a chute to fill the seed envelopes. The vibration of the bowl along with the speed of the chain that carries the packets will determine how much seed goes into each packet. Packet weights are checked for accuracy, and if they aren’t correct, we can adjust the bowl & the chain (one or the other or both) to make sure the correct amount goes into the packet. There is minor variation of the amount of seed that goes into each packet, so we always set these machines to overfill slightly.

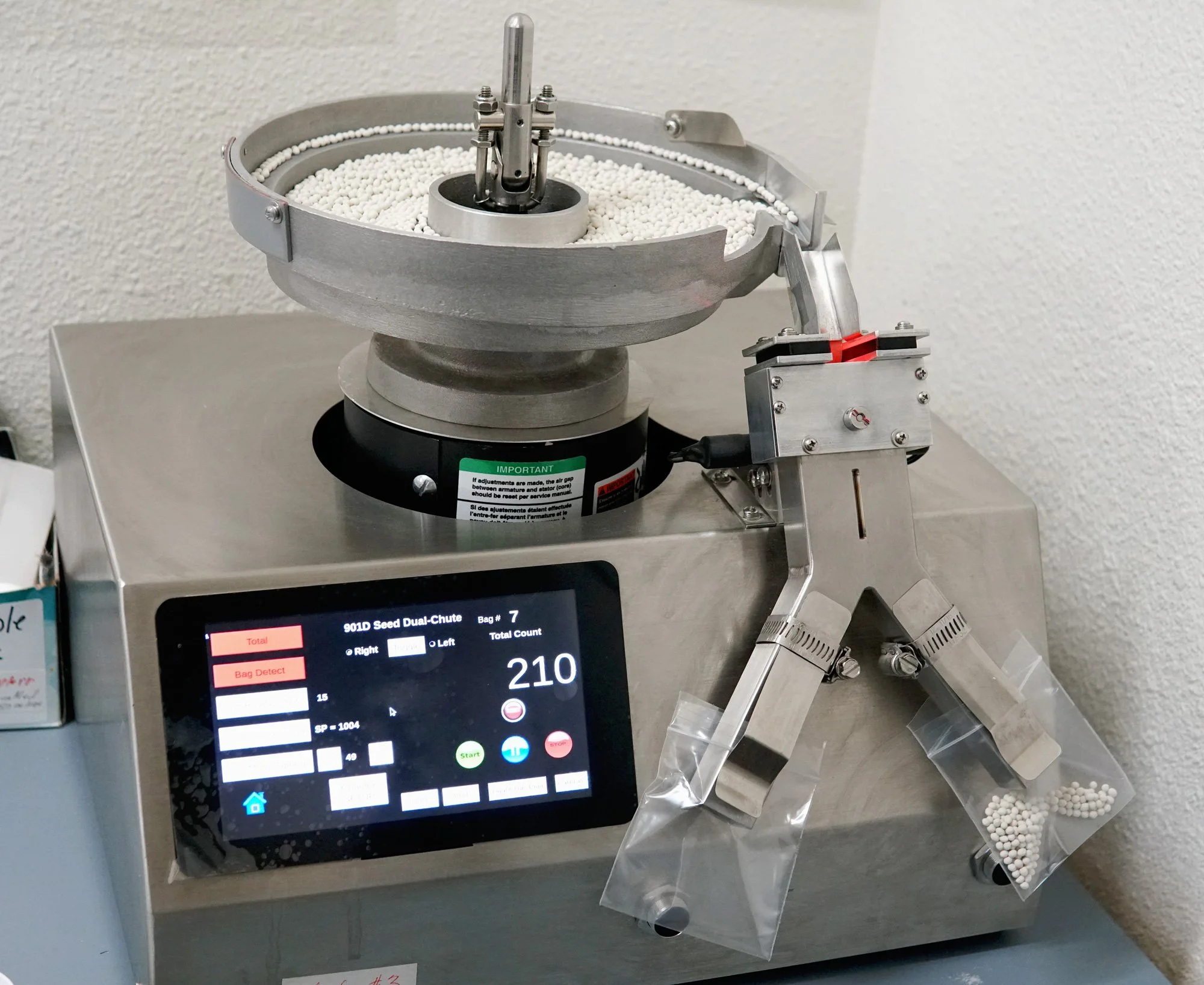

For seed packets that need to be filled by count (10 seeds, 100 seeds, etc.) we have seed counting machines. The machines tally each individual seed as it goes into the packet and displays that information on the machine’s screen, so we know the number going into each envelope is accurate.

Our larger seed packets that are filled by weight are filled by hand. We also hand-fill all our custom blends, such as our flower mixes. Just like with our automated machines, there can be minor variation of the amount of seed that goes into each packet, so our hand fillers always overfill slightly.

How do we decide which method of packet filling to use?

We have been filling seed packets for over 40 years and have gained extensive knowledge and experience to know which methods are best for each and every seed type. Quite literally every seed and size can be treated differently and could be counted, weighed, or filled by hand.

How many unique packets do we print & fill in a season?

We created and filled over 4,000 unique (size & variety) packets for this season, and that number increases each year.

How many packets can be manufactured in a day using our various methods?

Seed Pack – over 10,000 (per machine) depending on the weight and size of the seed.

Counting Machines – over 1,500 (per machine) depending on the number of seed that needs to be counted for each packet. The more seed that goes into each packet, the longer it takes. We sell seed counted packets as large as 100,000 seeds!

By Hand – over 1,000 (per person) depending upon the seed type and amount needed.

How do we store our seed?

We have temperature and humidity-controlled rooms that we refer to as cold rooms. With proper storage, most seed can be stored for many years. We still always test the germination every year to ensure the seed is viable before adding it into our packets and shipping it to your garden!

We hope you enjoyed this peek behind the curtain into our very busy seed filling department. It’s just one of the many teams here at Territorial Seed Company that works hard to help you succeed in your garden.

Author: Mel R